SIS系统

SIS系统技术说明书

SIS System Technical Specification

1、概念/Concept

SIS是安全仪表系统,根据美国仪表协会(ISA)对安全系统控制系统的定义而得名。也称紧急停车系统(ESD)安全连锁系统(SIS)或仪表保护系统(IPS),安全仪表系统是指,能实现一个或多个安全功能的系统。用于监视生产装置或独立单元的操作。如果生产过程超出安全操作范围,可以使其进入安全状态,确保装置或独立单元具有一定的安全度。安全系统不同于批量控制、顺序控制及过程控制的工艺连锁。当过程变量(温度、压力、流量、液位等)超限、机械设备故障、系统本身故障或能源中断时,安全仪表系统自动(必要时可手动)的完成预先设定的动作,使操作人员及工艺装置处于安全状态。SIS系统可用来实现一个和多个安全仪表功能的控制系统。主要为工厂控制系统中报警和联锁部分,对控制系统中检测的结果实施报警动作或调节或停机控制,是工厂企业自动控制中的重要组成部分。

SIS is a Safety instrumented system, named after the definition of the safety system control system by the American Instrument Association (ISA). Also called emergency shutdown system (ESD) safety interlocking system (SIS) or instrument protection system (IPS), Safety instrumented system refers to a system that can realize one or more safety functions. Used to monitor the operation of production devices or independent units. If the production process exceeds the safe operating range, it can be put into a safe state to ensure that the device or independent unit has a certain degree of safety. The safety system is different from the process interlocking of batch control, sequence control, and process control. When the process variables (temperature, pressure, flow, liquid level, etc.) exceed the limit, mechanical equipment failure, system failure or energy interruption, the Safety instrumented system automatically (manually if necessary) completes the preset action, so that the operators and process devices are in a safe state. The SIS system can be used to implement a control system for one or multiple safety instrument functions. Mainly for the alarm and interlocking parts of the factory control system, implementing alarm actions or adjusting or stopping control on the detection results in the control system is an important component of automatic control in factories and enterprises.

2、系统构成/System composition

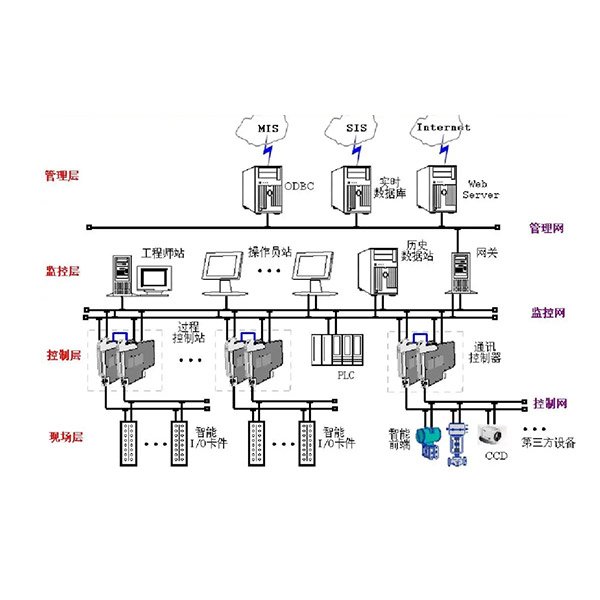

2.1、安全仪表系统主要包括测量单元、逻辑控制单元和执行单元,再配合相应的软件组成。通常与基本过程控制系统(如:DCS系统)有通讯要求,共同组成生产装置的过程仪表控制系统。

The Safety instrumented system mainly consists of measurement unit, logic control unit and execution unit, together with corresponding software. Usually, there are communication requirements with the basic process control system (such as DCS system), which together form the process instrument control system of the production device.

2.2、安全完整性等级/Safety Integrity Level

安全完整性等级是一种国际通用的“标准语言”,目的是用一种简单的方法来划分工艺装置中每个安全仪表回路的安全等级要求。是SIS系统设计中必须遵从的一个重要安全指标。

依据IEC标准由低到高划分为SIL1-SIL4, ISA 84.01标准划分为SIL1-SIL3,DIN V VDE0804标准由低到高划分为AK1-AI8,它们之间的对应关系如下。

Safety integrity level is an international "standard language", which aims to divide the safety level requirements of each safety instrument loop in the process unit in a simple way. It is an important safety indicator that must be followed in the design of SIS systems.

According to the IEC standard, it is divided into SIL1-SIL4 from low to high, SIL1-SIL3 from ISA 84.01, and AK1-AI8 from low to high according to DIN V VDE0804. The corresponding relationship between them is as follows.

安全完整性等级/Safety integrity level

2.3、安全生命周期/Safety Lifecycle

安全仪表系统的安全生命周期也是一个非常重要的概念,要保证工艺装置的安全生产运行,不但要选择合适的控制系统,而且对工艺过程的风险评估、安全回路等级划分和控制系统的维护管理也有严格要求。SIS系统的整个安全生命周期可分为分析、工程实施及操作维护3大阶段。在分析阶段,要辨识工艺过程的潜在危险,并对其后果和可能性进行分析,以便确定过程风险及必要的风险降低要求。工程实施阶段主要完成SIS的工程设计、仪表选型,安全逻辑控制器的硬件配置、软件组态以及系统集成,完成操作和维护人员的培训,完成SIS的安装和调试,以及SIS的安全验证。操作维护阶段在整个安全生命周期中时间区间最长,包括操作和维护、修改和SIS的停用。

The safety life cycle of the Safety instrumented system is also a very important concept. To ensure the safe production and operation of the process unit, not only the appropriate control system should be selected, but also there are strict requirements for the risk assessment of the process, the classification of the safety loop, and the maintenance and management of the control system. The entire safety lifecycle of the SIS system can be divided into three stages: analysis, engineering implementation, and operation and maintenance. In the analysis stage, potential hazards of the process should be identified, and their consequences and possibilities should be analyzed to determine process risks and necessary risk reduction requirements. During the implementation phase of the project, the main tasks are to complete the engineering design, instrument selection, hardware configuration, software configuration, and system integration of the SIS, as well as training for operation and maintenance personnel, installation and debugging of the SIS, and safety verification of the SIS. The operation and maintenance phase has the longest time interval throughout the entire safety lifecycle, including operation and maintenance, modification, and SIS deactivation.

在SIS系统设计选型后,要根据可靠性数据和操作模式,对安全仪表功能的危险失效概率或危险失效频率进行计算,评定是否满足目标安全仪表的功能安全要求。这是保证必要的风险降低和功能安全仪表功能安全的重要环节。同时,在SIS运行后,日常维护、修改管理、周期性检验测试、功能安全审计等也是功能安全的核心工作。

After the design and selection of SIS system, the dangerous failure probability or dangerous failure frequency of safety instrument function shall be calculated according to the reliability data and operation mode to assess whether it meets the Functional safety requirements of the target safety instrument. This is an important link to ensure necessary risk reduction and Functional safety and Functional safety of instruments. At the same time, after SIS operation, routine maintenance, modification management, periodic inspection and testing, Functional safety audit, etc. are also the core work of Functional safety.

无锡市惠华特种仪表有限公司

无锡市惠华特种仪表有限公司

移动电话:15716188608

公司电话:0510-85180508

传真电话:0510-88152298

05288518052885180528

地址:无锡市滨湖区蠡湖商务园23号

| * 联系人: | 请填写您的真实姓名 |

| * 手机号码: | 请填写您的联系电话 |

| 电子邮件: | |

| * 采购意向描述: | |

| 请填写采购的产品数量和产品描述,方便我们进行统一备货。 | |

| 验证码: |

|

相关资讯

| 我要评论: | |

| 内 容: |

(内容最多500个汉字,1000个字符) |

| 验证码: | 看不清?! |

惠华产品中心Product center

联系惠华

无锡市惠华特种仪表有限公司

移动电话:15716188608

公司电话:0510-85180508

公司电话:0510-88152298

公司地址:无锡市滨湖区蠡湖商务园23号

手机扫描二维码

手机扫描二维码

共有-条评论【我要评论】